About Us

SiChuan XiangYue Power Line Components Co., Ltd. (X.Y. Tower) is a comprehensive electrical power company established in 2008. X.Y. Tower specializes in providing a wide range of galvanized steel structures, focusing on power line towers up to 500kV, substation structures, communication towers, electrified railway structures, and more. The company spans 33,000 square meters and operates 10 automated production lines, with an annual production capacity of 40,000 tons.

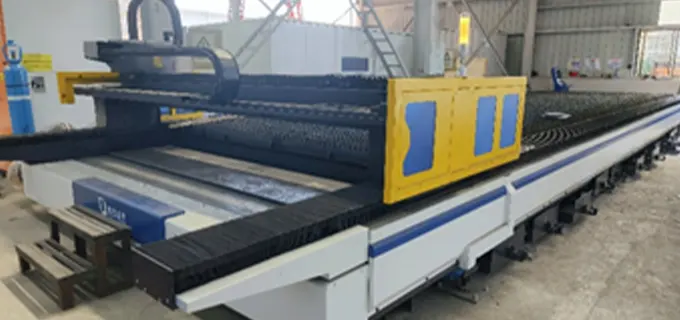

Our Equipments

Manufacture equipments(more than 100 sets):

The company is equipped with advanced machinery, including 16-meter CNC bending machines, 16-meter laser cutting machines, automatic angle steel lines, punching machines, CNC hydraulic punching machines, welding machines, and more.

Test Equipments:

The company utilizes advanced testing equipment such as digital hydraulic universals, ultrasonic flaw detectors, eddy current analyzers, weld flaw detection cells, coating thickness gauges, and more.

Design Software:

Design telecom towers using ANSI/TIA-222-G-2 standard software, and design electric poles to meet international standards.

Following Manufacture Standard

GB、EN、ASTM.

Customer Visit

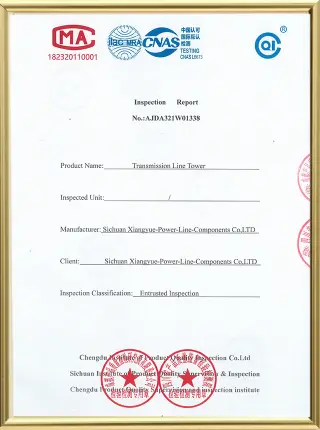

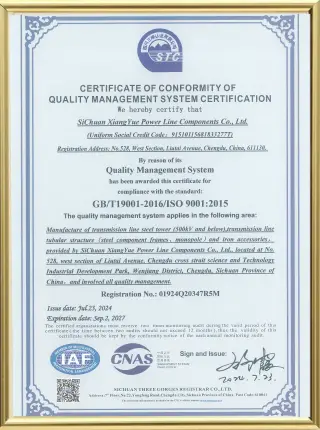

The company offers customized solutions and products tailored to meet the specific needs of customers. It maintains a stringent product quality management system and has successfully obtained ISO 9001 international quality certification.

Efforts as an eco-friendly company

Responsible business practices and sustainable economic growth have been at the core of X.Y. Tower since its inception.

Today, sustainability and economic development form the foundation of our mission and services, and are embedded in our systematic approach to work. We believe that a balanced approach between economic growth and environmental goals is both achievable and essential. We set clear environmental targets and objectives for our business, which are regularly monitored through management reviews and independent internal and third-party audits. At X.Y. Tower, we believe that every employee plays a key role in ensuring adherence to these environmental goals, objectives, and management standards. We are committed to leading in responsible HSE (Health, Safety, and Environmental) management within our industry.

Continual social contribution activities

o uphold this commitment and promote a culture of continuous improvement in our health, safety, and environmental responsibilities, the following requirements must be adhered to:

- Stay informed and comply with all current and future laws and regulations. Implement stricter standards and procedures within the company to ensure compliance.

- The health and well-being of employees is a top priority for X.Y. Tower. We are committed to maintaining a safe working environment, where all employees must wear protective equipment in the workshop and adhere strictly to safety protocols.

- Protect the environment by minimizing waste generation through various initiatives and reducing resource consumption wherever possible.

- Continuously identify potential areas for improvement in our HSE (Health, Safety, and Environment) management system and take proactive steps to implement necessary changes for better performance.