Contatc

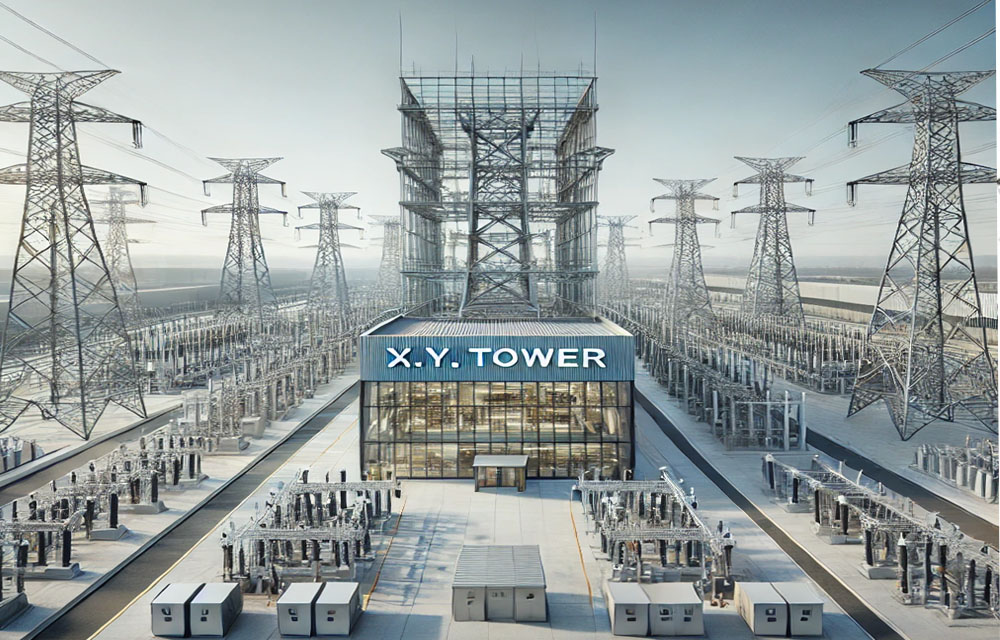

SiChuan XiangYue Power Line Components Co., Ltd. (X.Y. Tower): Pioneering Excellence in Galvanized Steel Structures

2025-02-01

Since its establishment in 2008, SiChuan XiangYue Power Line Components Co., Ltd. (commonly known as X.Y. Tower) has emerged as a leading force in the electrical power sector. With a comprehensive range of products, cutting-edge production technology, and a reputation for delivering high-quality galvanized steel structures, the company has made significant contributions to global power infrastructure. X.Y. Tower’s dedication to innovation and excellence has propelled it to the forefront of the industry, serving critical needs in power transmission, communication, and rail transport.

This blog delves into the key aspects of X.Y. Tower’s operations, product offerings, manufacturing capabilities, and the factors that have contributed to its impressive growth and reputation.

A Vision for Excellence: The Journey of X.Y. Tower

Founded in 2008, X.Y. Tower was born out of a vision to provide robust, reliable, and long-lasting solutions for the rapidly growing power industry. At its core, the company is dedicated to producing top-tier galvanized steel structures that ensure the stability of essential infrastructure such as power lines and communication systems. Over the past 15 years, X.Y. Tower has grown significantly, evolving from a regional supplier to a globally recognized brand.

What sets X.Y. Tower apart is its commitment to continuous improvement and technological innovation. From power grids and substations to railway and communication networks, the company’s solutions have become indispensable in building sustainable and resilient infrastructure worldwide.

Diverse Product Offerings: Meeting Global Infrastructure Needs

X.Y. Tower’s product range is designed to meet the varied demands of different industries, with a strong emphasis on quality, precision, and durability. The company specializes in manufacturing galvanized steel structures for several key applications, including:

1. Power Line Towers (Up to 500kV)

One of X.Y. Tower’s flagship products, power line towers, plays a vital role in the transmission of electricity across vast distances. These towers are engineered to withstand extreme environmental conditions, ensuring uninterrupted power supply. With capacities reaching up to 500kV, they are suitable for large-scale power grids, serving industrial, residential, and commercial sectors.

2. Substation Structures

Substations are the backbone of any electrical grid, responsible for transforming voltage levels to ensure efficient energy distribution. X.Y. Tower’s substation structures are designed with precision to support critical equipment and ensure operational safety and reliability. These structures are customizable to meet specific project requirements, providing flexibility to engineers and developers.

3. Communication Towers

In an age where communication is essential, X.Y. Tower’s solutions extend to the production of durable communication towers for telecommunication networks. Whether for cellular networks, radio stations, or broadcasting systems, the company’s towers are built to provide long-lasting performance and structural integrity.

4. Electrified Railway Structures

With the expansion of electrified railway networks globally, X.Y. Tower plays a crucial role in providing steel structures that support overhead wiring systems. These structures are essential for ensuring the safe and efficient operation of electric trains, contributing to the advancement of sustainable transport solutions.

5. Customized Galvanized Steel Solutions

Beyond its standard offerings, X.Y. Tower provides customized solutions to meet the unique requirements of specific projects. Its design and engineering teams work closely with clients to develop tailored structures that address their individual needs while ensuring compliance with international standards.

State-of-the-Art Manufacturing Facilities

One of the key drivers of X.Y. Tower’s success is its modern and well-equipped manufacturing facility. Located on a sprawling 33,000-square-meter site, the facility is home to 10 automated production lines that are designed to optimize efficiency and maintain strict quality control standards.

Production Capacity and Efficiency

With an annual production capacity of 40,000 tons, X.Y. Tower is well-positioned to handle large-scale projects and meet the growing demand for galvanized steel structures. The company’s automated production lines enable faster turnaround times while minimizing errors, ensuring that every product meets or exceeds customer expectations.

Quality Control and Testing

Quality is at the heart of X.Y. Tower’s operations. The company has implemented a rigorous quality control system that involves multiple stages of testing and inspection. From raw material selection to final product evaluation, every step of the production process is monitored to guarantee compliance with international standards such as ISO 9001.

The company’s in-house testing laboratory is equipped with advanced equipment for mechanical testing, chemical analysis, and corrosion resistance evaluation. This ensures that all products can withstand the harshest environmental conditions, including extreme temperatures, humidity, and high wind loads.

Engineering Expertise and Innovation

X.Y. Tower’s engineering team is central to its ability to deliver innovative and reliable solutions. Comprising experienced designers, structural engineers, and technical specialists, the team leverages advanced software and design tools to create optimized solutions for complex projects.

Customization and Design Flexibility

Whether clients require standard designs or customized solutions, X.Y. Tower’s engineering team is capable of accommodating diverse specifications. By collaborating closely with clients, the company ensures that all structural requirements, environmental factors, and safety considerations are addressed in the design process.

Focus on Sustainability

Sustainability is a growing concern in modern infrastructure development, and X.Y. Tower is committed to promoting eco-friendly practices. The company employs environmentally responsible manufacturing processes, including the use of recyclable materials and energy-efficient production techniques. Additionally, its galvanized steel structures are designed to have long service lives, reducing the need for frequent replacements and minimizing environmental impact.

Global Reach and Notable Projects

Over the years, X.Y. Tower has established a strong presence in both domestic and international markets. The company has successfully delivered projects across Asia, Africa, the Middle East, and South America, earning a reputation for reliability and quality.

Noteworthy Projects

- Large-Scale Power Transmission Projects: X.Y. Tower has contributed to the development of major power grids, including 500kV transmission lines in regions prone to extreme weather.

- Telecommunication Networks: The company has supplied communication towers for national cellular networks, enhancing connectivity and digital access.

- Railway Electrification Projects: Its railway structures have played a crucial role in the expansion of high-speed rail networks, promoting sustainable transportation.

Commitment to Customer Satisfaction

X.Y. Tower’s success is rooted in its customer-centric approach. The company values long-term partnerships and prioritizes customer satisfaction at every stage of the project. From initial consultations to post-installation support, X.Y. Tower ensures that clients receive comprehensive service and technical assistance.

After-Sales Support

The company offers extensive after-sales support, including maintenance guidance, troubleshooting, and replacement services. This commitment to customer service has helped X.Y. Tower build a loyal client base and foster repeat business.

Challenges and Future Outlook

Despite its success, X.Y. Tower faces challenges common to the industry, such as fluctuating raw material prices and evolving regulatory requirements. However, the company’s proactive approach to risk management and its investment in innovation have enabled it to navigate these challenges effectively.

Looking ahead, X.Y. Tower aims to expand its production capacity and explore new markets, particularly in regions with growing infrastructure needs. The company also plans to enhance its research and development efforts to stay ahead of emerging trends and technologies.

Conclusion

SiChuan XiangYue Power Line Components Co., Ltd. (X.Y. Tower) stands as a testament to what can be achieved through innovation, dedication, and a commitment to quality. As the world continues to invest in critical infrastructure, X.Y. Tower is well-positioned to play a pivotal role in shaping the future of power transmission, communication, and sustainable transport. With its robust manufacturing capabilities, engineering expertise, and global reach, the company is poised to remain a trusted partner for infrastructure development projects around the world.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.